Jimmyhoffa816

Active Member

I've got a 1998 Freightliner classic with a 2000 N14 CelectPlus 525. From the beginning I got the engine from shop that said it only had 400k on over haul. So I bought engine, from Start it had a miss, had the ECM rebuilt, new fuel lines, bypassed the ECM cooling plate, replaced fuel shut off valves on top of transmission with non valve T's, finally found out it was number 6 injector. So I replaced 5&6 together, ran fine but was smoking blue white at idle, and using 1 gal of oil every 2k(it does have leaks) and had some pretty good blow by, oil painting 18-20 at 700rpms and 32-35 at 1200 rpms and up, alright so I tore all three heads off, cylinders and Pistons look like they have less than 200k. Took heads to machine shop, they said valve seats were shot on exhaust side and not much better on intake, and injector cups shot. So did complete valve job and new injector cups. Got heads back block is in decent shape. Smoothed and reinstalled heads new gaskets all the way up. Overhead ran. New fresh coolant. Oil. All filters new. Fired up runs good, went from kck to Seattle and back to smoking at idle. Exhaust Smells of fuel. Oil painting unchanged. No fluids mixing. Blow by is not nearly as bad. Used 1.25 gal of oil for 3900 miles. Swapping gears only gives a little black. But no smoke while cruising. Plenty of power, more than it had before head job. But when idle white/blue. Ok so I'm thinking I've got an injector issue, over fueling. Older guy that taught me alot about the N14 used to use a heat gun on exhaust ports to check for over fueling injectors when the truck wasn't missing for interior cut out yet (unplugging each injector) so I did that let idle for 30 mins at 1000rpms and got following results:

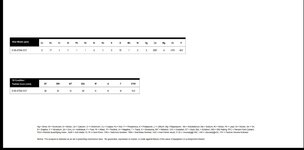

#1-187

#2-222

#3-230

#4-198

#5-197

#6-175

So after this I'm thinking my issue might lie in #2&3 since they are alot hotter than the others, number 5&6 are new.(I know it's better to replace 6 at a time but didn't/don't have funds) so I'm thinking of replacing 2&3 with new injectors, then I will replace last two next pay check. Then all six will be new, MPG has been around the same from day one till now 4.7-5.3, I have another classic with same engine getting 5.5-6.5, so I know it can do better. Any thoughts on if I'm on the right track here would be greatly appreciated

#1-187

#2-222

#3-230

#4-198

#5-197

#6-175

So after this I'm thinking my issue might lie in #2&3 since they are alot hotter than the others, number 5&6 are new.(I know it's better to replace 6 at a time but didn't/don't have funds) so I'm thinking of replacing 2&3 with new injectors, then I will replace last two next pay check. Then all six will be new, MPG has been around the same from day one till now 4.7-5.3, I have another classic with same engine getting 5.5-6.5, so I know it can do better. Any thoughts on if I'm on the right track here would be greatly appreciated

Last edited: